This homeowner is moving their new standby generator from the curb to a custom concrete pedestal at their home after Hurricane Katrina left them without power. Tight space and a heavy generator necessitated some heavy equipment and the help of friends. Note the lift straps attached to the pipes inserted into the generator lift holes.

Photo provided by Cyril Laan

Moving a Heavy and Awkward Standby Generator Requires Muscle or the Right Equipment

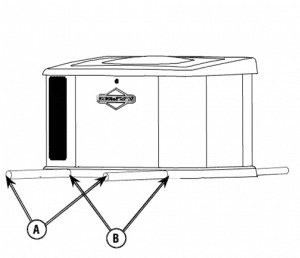

This 26kW Briggs and Stratton Generator ‘s shipping weight is more than 625 pounds. One of the Lifting Holes is shown on the black trim right side—A second lifting hole is hidden by the transfer switch and gateway. Lifting holes accomodate iron pipes.

Moving and placing a standby generator is not an easy task. The units are heavy, with shipping weights that approach 600 pounds for 20 kilowatt generators, and more than 450 pounds for 10 kilowatt units. The weight is not balanced and the center of gravity is closer to one end or side of the generator.

If you’re going to move a generator yourself, you will need some lifting equipment and one other person, or four to eight physically-fit people with strong backs and good balance. The methods specified by different manufacturers are similar, but are not always exactly the same. Check your installation or owners manual for specifics.

WARNINGS

- Don’t attempt to do the job alone. Have a helper who can watch the load and the surroundings while you operate the lifting equipment.

- Watch out for power lines and never allow the lifting equipment to contact them.

- Always lift the generator with lifting pipes inserted through the lifting holes. Don’t allow lifting cables or chains to contact the roof of the generator. Don’t attempt to lift the generator by the lifting eyes.

- Never lift the generator by the roof, which will damage the generator and void the warranty.

- An Air Cooled Standby Generator weighs between 350 and 625 pounds. Lifting equipment must have the capacity for the weight or have enough people are on hand to lift and move the unit.

Transport Cart Method

The Cart Assembles Directly to the generator. An experienced installer can move a generator with a transport cart without any other help. Most people without experience should have at least one helper. Methods vary by brand, but the same general procedure works for most.- Remove the shipping brackets that hold the generator to the pallet.

- Slide the lifting pipes through the lifting holes.

- Attach the wheel frames to the lifting pipes.

- Add the side rails to the wheel frames and attach the handle to the side rails

- Pull the handle back to lift the generator off the pallet.

- Move the generator to the generator pad, the poured slab, or ground installation location.

Warning: Moving a heavy generator up or down a slope requires the help of a second or third person.

Manual Lift Method

Insert iron pipes into the lifting holes. Each person lifting should bend at the knees (squat), grasp the pipe, and lift together.

Lifting holes on the front and back of the generator accept a 3/4-inch or 5/8-inch piece pipe. Use two lengths of 60-inch-long, schedule-40, steel pipe inserted through the lifting holes. Locate more people on the heavier end or side so that the group as a whole bears the weight evenly. The pipes act as handles to allow lifting and carrying the generator unit.

Each person should lift using muscles in their legs, not in their back. Bend at the knees (squat), without bending at the back, and grasp the lifting pipe. When everyone is ready, lift the generator straight up and move it to the required location. Set the unit down the same way it was lifted―by bending at the knee and not at the back.

After the generator is resting in its final location, the pipes are withdrawn.

Lifting With Equipment

Hold Lifting Pipes in Place with Clamps, Add chains and separate with a lifting bar before using a crane or hoist to lift and move the generator.

One person should operate the hoisting equipment while a second person observe the lift. The observer should watch for power lines and other obstructions while hoisting and moving the generator. Never attempt to lift a generator alone.

Move the generator to the final location, lower it and remove the lifting chains or cables and the pipes.

Updated October 20, 2022